400 tons of pellets per year

In September the Uranium Operations (UO) division was qualified by the French company Framatome. From now on manufacturing of AFA 3G design pellets will become a more advanced process based on the use of the most state-of-the-art equipment.

Qualification of the production line for uranium dioxide pellets is the result of four years of the UO «R» workshop operation. It was the final stage of the pellets production upgrade project which was started in 2017. At that time the qualified process allowed manufacturing of no more than 150 tons of pellets per year. However, to meet the needs of the FA fabrication plant under construction and also the Chinese companies it was necessary to increase the capacity to 400 tons of pellets per year. And that was done! For that purpose Ulba Metallurgical Plant (UMP) upgraded the existing equipment and also purchased new additional units.

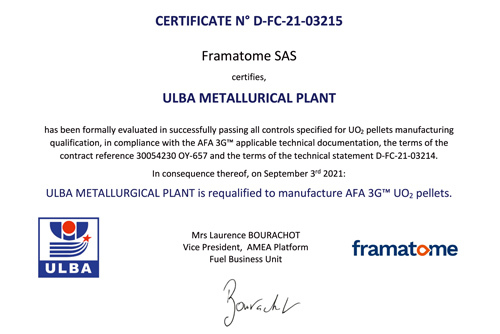

According to the standards the new equipment used in the technological process should be qualified by the French company Framatome as the owner of the AFA 3G design pellets technology. Therefore, in January 2021 a contract for the requalification of the pellets production line was signed between UMP and Framatome. In April 2021 upon obtaining any required permits the requalification contract entered into force.

For five months dozens of meetings and consultations with French colleagues were held, hundreds of documents regulating technological operations were developed – from receiving the input materials to packaging of pellets. More than 60 lots of finished products were manufactured, analyzed and tested, test results were statistically processed and a huge amount of reporting documentation was prepared. In July, a French expert worked at the UO site and witnessed any stages of the technological process.

As a result of the works performed a final report was issued which consisted of 630 pages! It was reviewed and approved by the French party. On the basis of that report Framatome granted a certificate to UMP which confirmed that the plant could produce AFA 3G design pellets at the upgraded production line.

A significant contribution to the successful qualification was made by Alexey Boltanov, UO Deputy Director; Alexander Eichler, Head of Export Contracts Group, Export Contracts Department; Vladislav Kogay, Head of Pellets Manufacturing Division, «R» Workshop; Anton Dolganov, Process Engineer, Pellets Manufacturing Division, «R» Workshop; Natalya Yaroshenko, former Head of Uranium Laboratory, Research Center; Timur Aldazharov, Senior Research Engineer; Farhad Sattarov, Head of PTD, UO; Alexander Skorikov, PG Head, UO; Vladimir Bespalov, TG Process Engineer, UO; Sergey Kim, TG Head, UO; Galina Anissimova, Manager of M&SP, UO; Olga Magherramova, Process Documentation Management Expert, TG, UO; Irina Malyutina, Testing Laboratory Head, UO, RC; Olga Kondratenko, Head of TCB, UO, RC; Viktor Semyonov, Senior Metrologist, and Oleg Likhachev, Instrumentation Engineer, «R» Workshop.