Center of science

The rich and glorious history of science in Ulba Metallurgical Plant began in the middle 50s of the last century.

AT THE ORIGINS

By 1955, two main areas of activity were determined at the plant – production of beryllium for the needs of military, space, radio-electronic equipment and production of uranium compounds for nuclear energy and military equipment.

In January of the same year, by order of the plant, a Research Group on Technology was organized as part of the Central Plant’s Laboratory (CPL). In March 1956, a Research Laboratory (RL) was established. It includes Metallurgical, Process, Analytical departments and Regulatory Research Group.

ESTABLISHMENT AND DEVELOPMENT

From 1961 to 1974, during the leadership of Vladimir Potanin, Research Laboratory turned into an independent division – Central Research Laboratory (CRL). The laboratory has grown both numerically and qualitatively. In 1965, Central Research Laboratory and Central Laboratory of Automation moved to a new building, which was built according to the special project and was intended to work with isotopes, uranium, beryllium and tantalum compounds. Many employees of Central Research Laboratory at that time entered graduate school, defended dissertations on topics relevant to the plant.

The late 70s and 80s were a period of progressive development of science at the plant. Scientific researchers were faced with colossal tasks. So, before Tantalum Operations, it became necessary to develop and create industrial production of finely dispersed, pure, high-capacity tantalum powders. Researchers of Central Research Laboratory have developed a process and equipment for its production, created an effective extraction technology for tantalum production.

Research and development work was carried out in the technology of fuel production for atomic-powered submarines and fuel pellets for RBMK-1000, 1500, VVER-1000 reactors.

Also, the plant’s science was directly involved in the development of production processes for beryllium extraction from sulfate pulps, in the manufacture of insulating and switching units for thermoelectric generators from beryllium oxide. However, these are just a few of the projects...

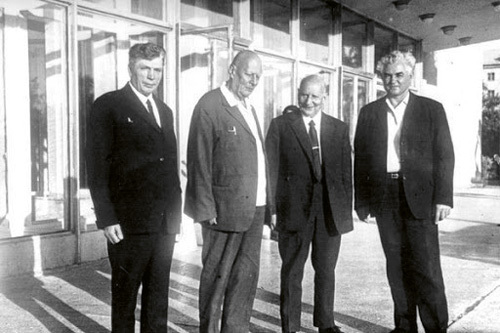

The greatness of UMP’s scientific thought can be judged by the level of gurus who visited the plant, with whom the best minds of the plant worked side by side. Among them is a metal scientist, academician of the USSR Academy of Sciences, twice Hero of Socialist Labor, Laureate of Lenin and four Stalin prizes – Andrey Bochvar and Soviet physicist, academician of the USSR Academy of Sciences, doctor of physical and mathematical sciences, professor, three times Hero of Socialist Labor, President of the Academy of Sciences – Anatoliy Alexandrov.

In the 90s, Ulba science was going through hard times. The plant was renamed. It was used to create and transform the main and auxiliary productions. But no matter how hard it was, science has always remained a part of Ulba Metallurgical Plant.

SCIENCE TODAY

Scientific Center of UMP JSC is one of the three scientific centers of NAC Kazatomprom. Now it employs 88 people. The average age of employees is 45 years.

The center continues to develop and implement technologies and new ideas, ranging from extraction of minerals to high-tech finished products of the main industries.

Main achievements of the plant’s scientists today are:

– development of technology for the production of uranium tetra-fluoride, U3O8, ion-exchange extraction, production of fuel pellets for nuclear power plants, including pellets of modern design, as well as dilution of high-enriched uranium;

– development of technology for soda-sulfate opening and an ammonia-alkaline scheme for precipitation of beryllium hydroxide, decomposition, reduction and refining of copper, aluminum and nickel master alloys, technology for the production of beryllium oxide powders and products from it, intermetallic compounds based on beryllium and other non-ferrous metals;

– development of technology for raw materials acid opening and extraction of tantalum and niobium from slurries, production of potassium fluor tantalate, pentoxides, ferroniobium and aluminum niobium, powders and rolled products based on tantalum and niobium, flotation concentration of fluorspar concentrate, production of hydrofluoric acid;

– development of technology for ore enrichment from the Ermakovskoye deposit, associated extraction of rare metals and rare-earth metals from solutions of uranium underground leaching.

Natalya Apanasenko